artistryprofessionals

ANYCUBIC 405 nm Standard Resin V2 Quick Curing SLA UV Curing 3D Printer Materials Resin For LCD 3d Printer Mono M5s Mono X 6Ks

ANYCUBIC 405 nm Standard Resin V2 Quick Curing SLA UV Curing 3D Printer Materials Resin For LCD 3d Printer Mono M5s Mono X 6Ks

13 in stock

Regular price

$34.99 USD

Regular price

$28.54 USD

Sale price

$34.99 USD

Unit price

per

Shipping calculated at checkout.

Couldn't load pickup availability

SPECIFICATIONS

Brand Name: PHOTON

Form: Liquid

Hign-concerned Chemical: None

Model Number: 405nm UV Resin

UV wavelength: 365-405 nm

Density: 1.05-1.25 g/cm3

Tensile strength: 35-45 MPg

Heat deflection temp: 60-65°C

Viscosity: 250-350 cPimPas

Elongation at break: 25-30%

Felxural modulus: 1500-2100MPa

Shelf life: 1.5 Year

Molding shrinkage: 4.3-5.6%

Flexural strength: 40-50 MPa

Hardness: 80-83D

Normal exposure time: 1.5-3 s

Bottom exposure time: 20-40s

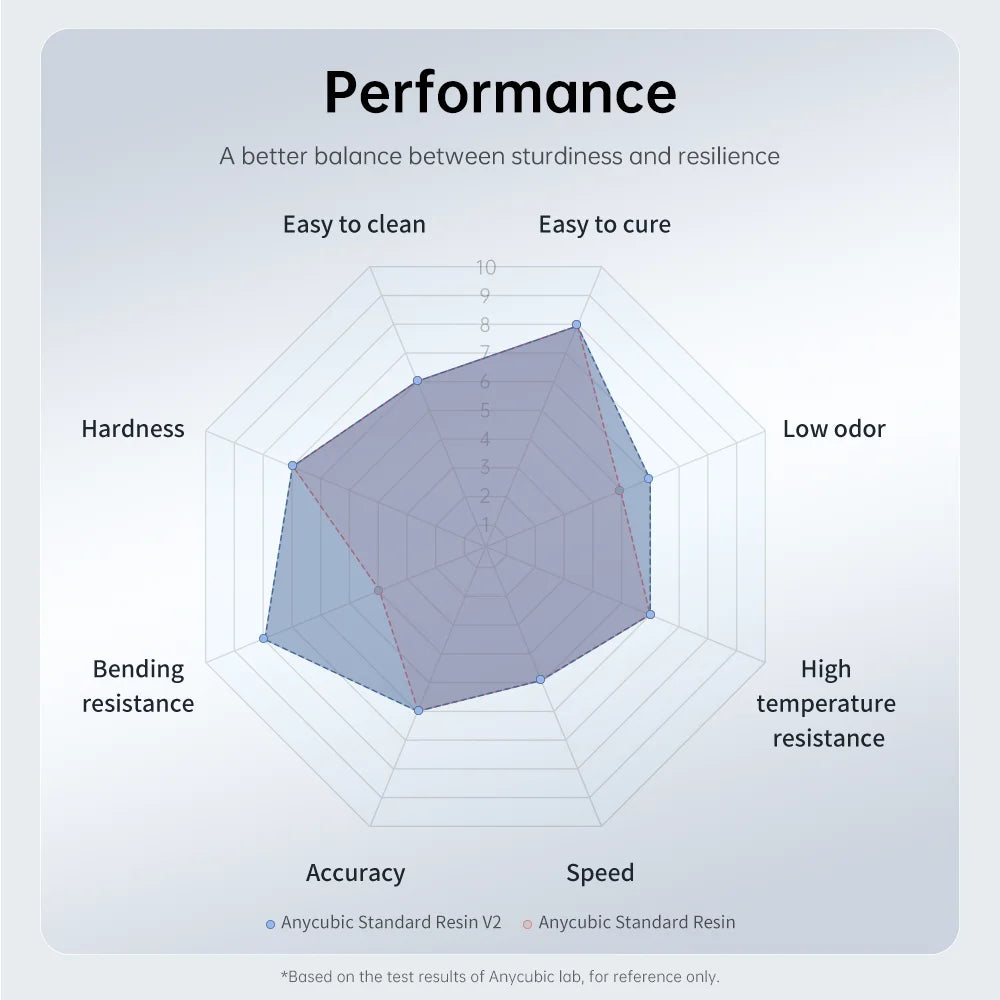

Anycubic Standard Resin V2

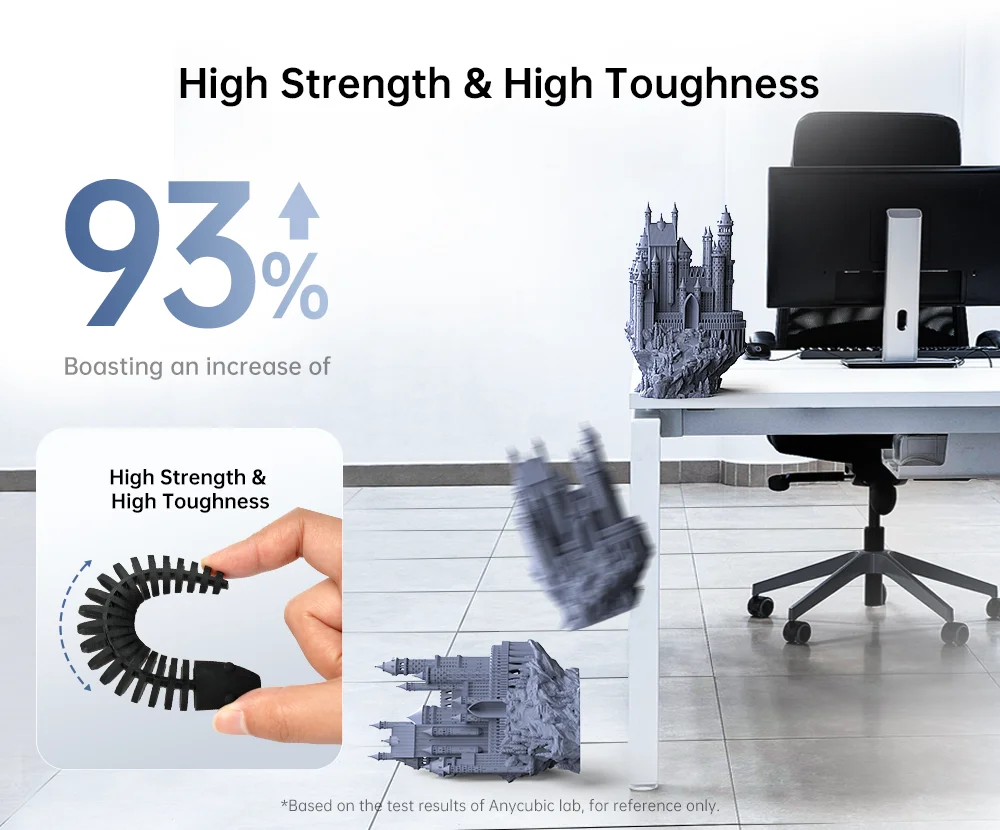

High Strength & High Toughness | Lower-Odor | Wide-Range of Applications

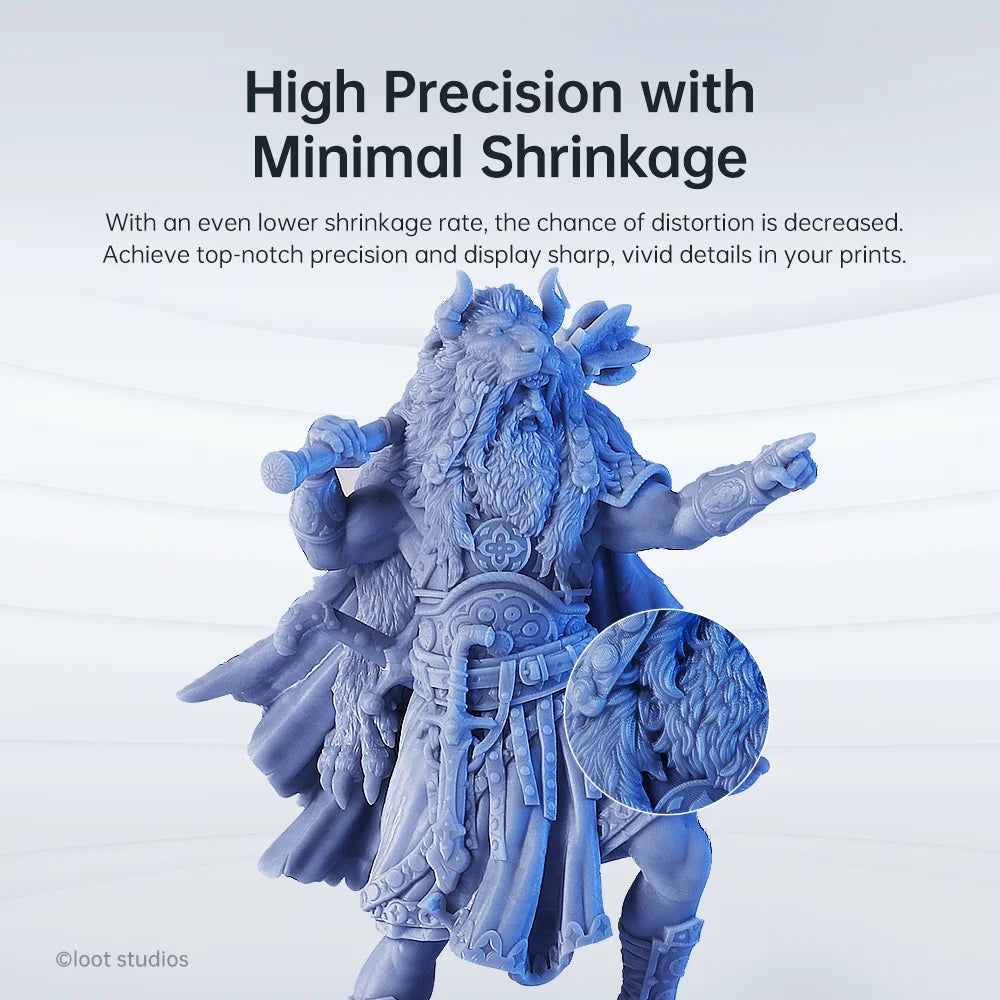

High Precision with Minimal Shrinkage

Based on the classic Anycubic standard resin, the Anycubic standard resin V2 further enhances toughness, boasting an increase of 93% in elongation at break. The finished models are resistant to impact, durable, and less prone to breaking, while still maintaining a certain degree of flexibility.

Lower-Odor

By upgrading the resin formula, the resin odor has been significantly reduced, creating a more comfortable printing environment for users.

High Precision with Minimal Shrinkage

With an even lower shrinkage rate, the chance of distortion is decreased. Achieve top-notch precision and display sharp, vivid details in your prints.

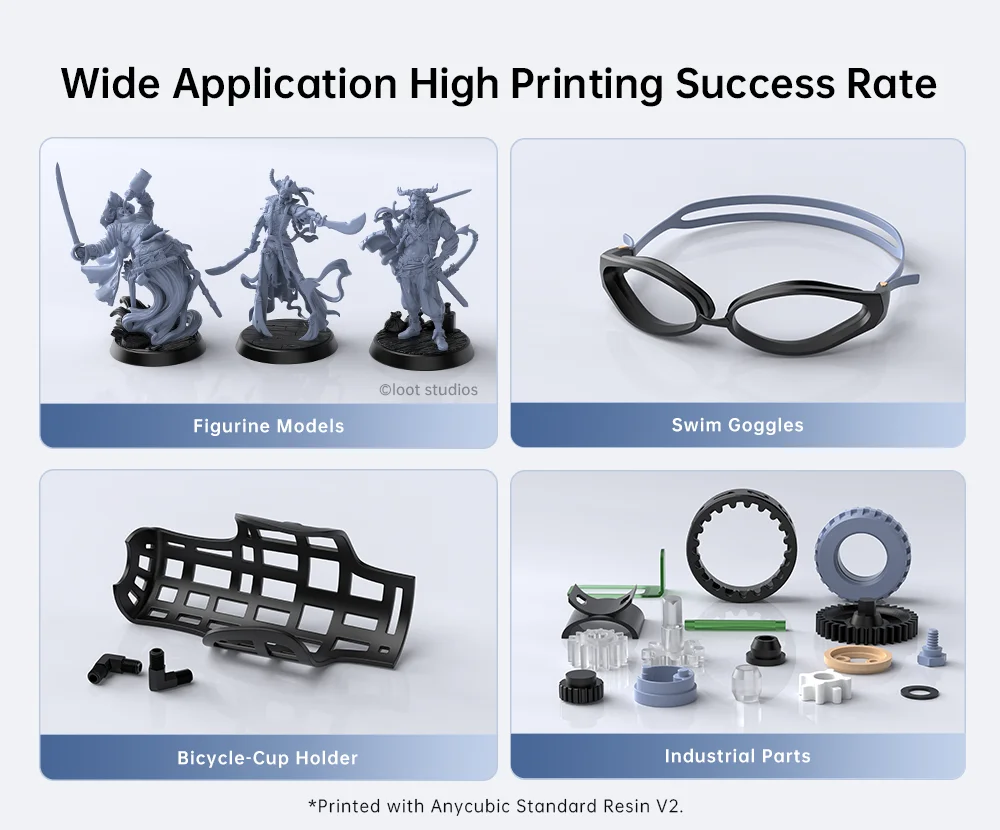

Wide Application High Printing Success Rate

As an entry-level resin, Anycubic Standard Resin V2 with a high success printing rate at the same time, is suitable for printing high intensity models that require high strength and toughness, such as industrial parts, assemblies, tools, architectural models, prototype proofing, figure design, etc.

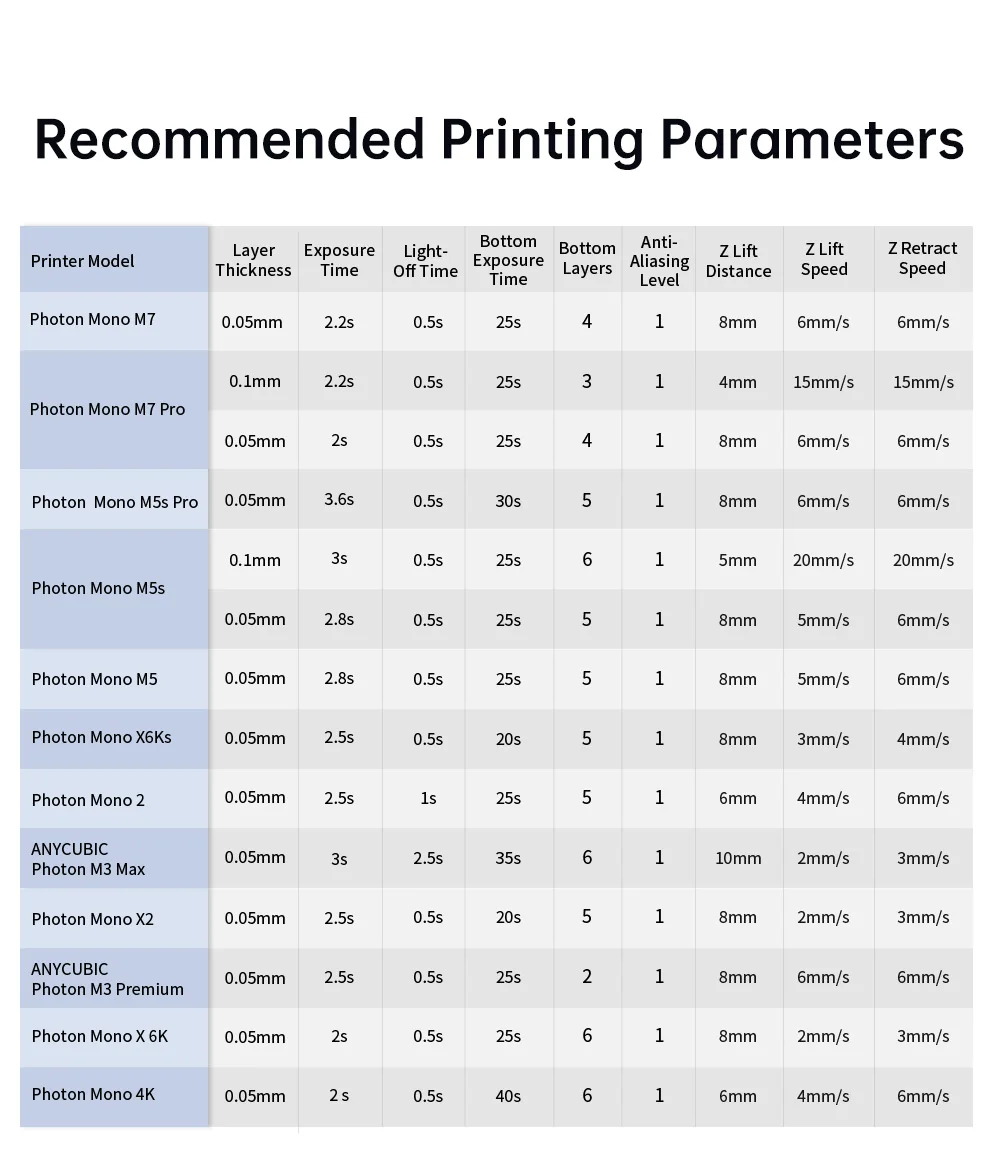

Resin Parameters

UV wavelength:365-405 nm

Density:1.05-1.25 g/cm3

Tensile strength:35-45 MPg

Heat deflection temp:60-65°C

Viscosity:250-350 cPimPas

Elongation at break:25-30%

Felxural modulus:1500-2100MPa

Shelf life:1.5 Year

Resin wash:Alcohol

Molding shrinkage:4.3-5.6%

Flexural strength:40-50 MPa

Hardness:80-83D

Normal exposure time:1.5-3 s

Bottom exposure time:20-40s

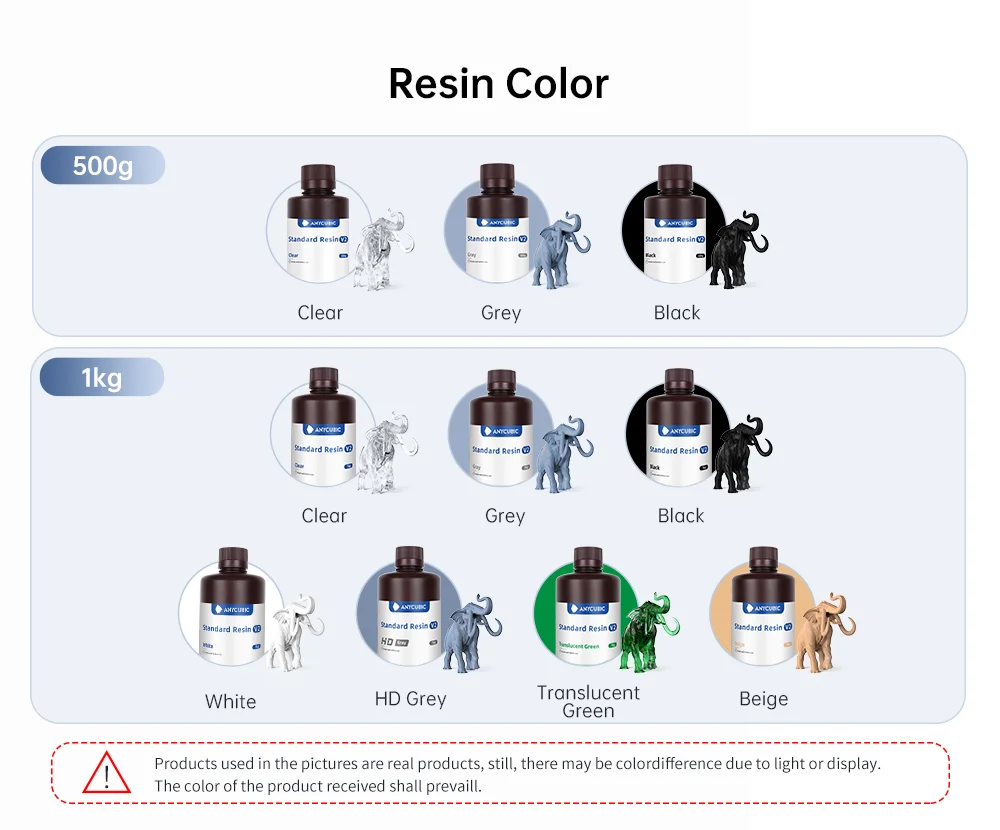

Color

High Compatibility

Compatible with 365-405nm wide band, suitable for most LCD and DLP light-curing 3D printers on the market, and easier to clean, helping novice users get started quickly.